CNC tube cutting machine is a high-precision industrial equipment that uses computer numerical control (CNC) technology to automate the cutting of tubes and pipes.

Discover Our Story

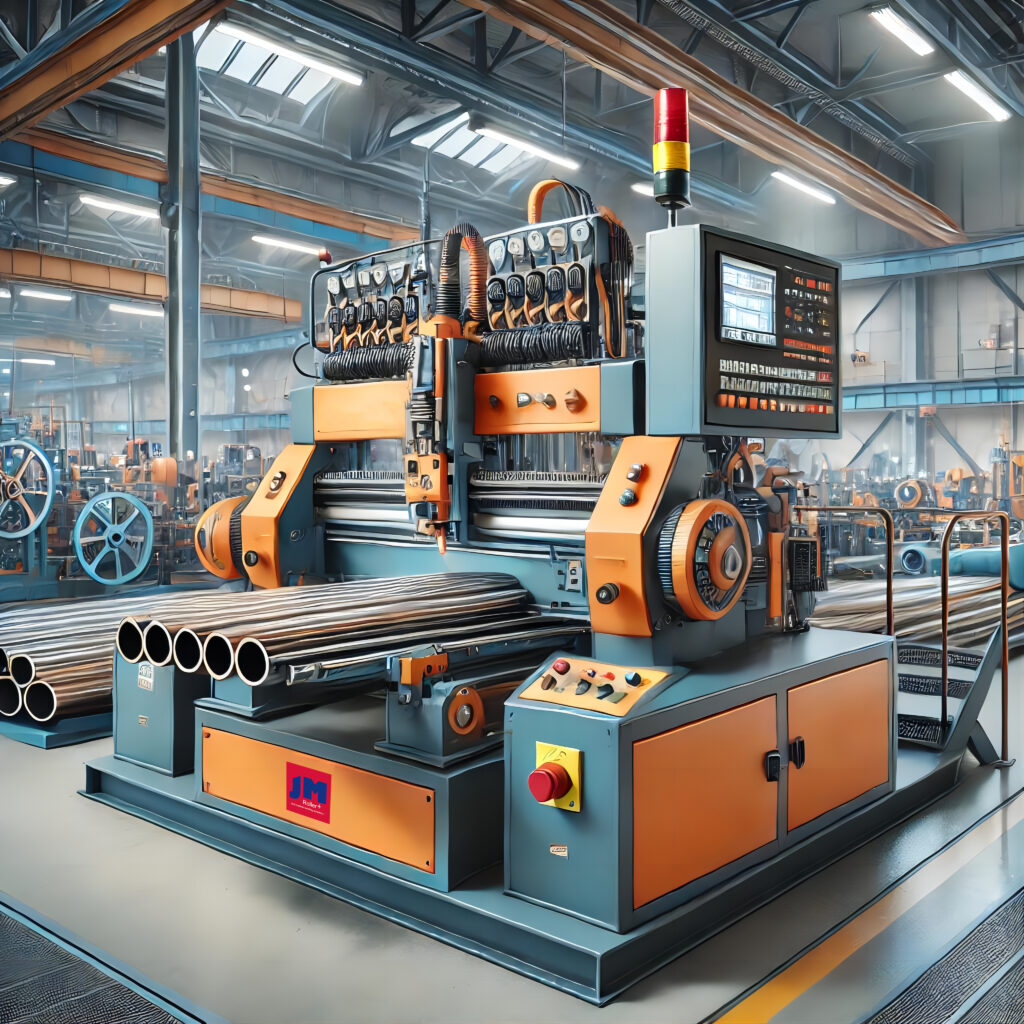

About CNC Pipe Cutting Machine

It is widely used in industries such as construction, automotive, aerospace, and manufacturing, and can efficiently and accurately cut tubes of various materials such as steel, aluminum, copper, and plastic.

Advantages of JM-HI CNC Pipe Cutting Machine

About our design

01

High Precision and Accuracy

CNC tube cutting machines are able to cut according to pre-programmed instructions, ensuring extremely high precision and consistency in every cut. This is especially important for applications that require tight tolerances and high-quality surfaces.

02

Versatility

The machine is capable of handling a variety of materials (such as steel, aluminum, copper and plastic) and different sizes of tubes, suitable for multiple industries and application scenarios. This versatility makes it a valuable asset in any manufacturing environment.

03

Improve production efficiency

The automated cutting process greatly reduces manual intervention and improves production speed and efficiency. The operator only needs to set the parameters and programs, and the machine can perform the cutting task efficiently, saving a lot of time and labor costs.

04

Reduce material waste

High-precision cutting and optimized cutting path design can minimize material waste and improve material utilization. This not only saves costs, but is also more environmentally friendly.

04

Consistency and repeatability

CNC technology ensures that the results of each cut are exactly the same, whether it is mass production or small batch customization, which is crucial for product quality control and brand reputation.

06

Improve safety

Automated operation and closed cutting environment reduce the operator’s direct contact with cutting tools and hot materials, reducing the risk of work-related injuries. In addition, the machines are usually equipped with advanced safety devices and alarm systems to further ensure safe operation.

Technical Parameters

Technical Specifications

This is the specification of the Automatic Cutting Pipes Machine we are currently using. If you have any special requirements, please let us know and our engineers will build an Automatic Cutting Pipes Machine specifically for your factory.

Applications

Mostly used in the construction industry, pipeline industry, automotive industry, manufacturing industry, oil and gas industry, etc.

FAQ

What materials can the Automatic Cutting Pipes Machine handle?

The machine can cut various materials including steel, aluminum, PVC, copper, and other metals and plastics.

Can the machine cut pipes to different lengths?

Yes, the machine has programmable settings that allow it to cut pipes to specific lengths as per user requirements.

How does the machine ensure cutting precision?

The machine is equipped with advanced cutting technology and a digital control panel, ensuring high precision and consistency in cuts.

What is the cutting speed of the machine?

The cutting speed is adjustable and can go up to 120 cuts per minute, depending on the material and pipe dimensions.

How user-friendly is the machine?

The machine features an intuitive control panel with a touch screen interface, making it easy to operate and monitor.

Can the machine be customized for specific cutting tasks?

Yes, the machine has adjustable settings and can be customized to meet specific cutting requirements for different applications.

Contact Us

If you have any more questions or need further information, please feel free to contact us.